Ananda produces millions of e-bike motor systems each year, making it one of the largest e-bike motor manufacturers in China

One of my biggest takeaways from China Cycle and the factories I toured was the amount of new e-bike technology being developed in China. I’m tired of getting comments from American consumers who have this idea in their head that Chinese Manufacturing = cheap and low-quality products.

Nothing could be further from the truth, at least with e-bike motor systems.

We had the opportunity to tour one of the e-bike motor factories and headquarters of Ananda Drive Technology, the company who won the Gold Creative Award at China Cycle 2025 for the development of their R900 3-speed automatic shifting rear hub motor.

The motor’s capabilities were impressive on their own. However, after touring Ananda’s production and testing facilities, I don’t think Ananda is just a one-hit wonder – it’s a brand we expect to see more OEMs choose for their e-bike systems going forward.

color: #d2d1d1; margin-bottom: 20px;”>

Who is Ananda?

Photo of Ananda’s factory in Jiangsu

Ananda may not have the same brand recognition among consumers as Bosch, Shimano, or even Bafang, but behind the scenes they’ve been a major player since 2011. Headquartered in Shanghai, Ananda designs and manufactures complete e-bike drive systems (everything but the battery) for a number of large, well-known brands.

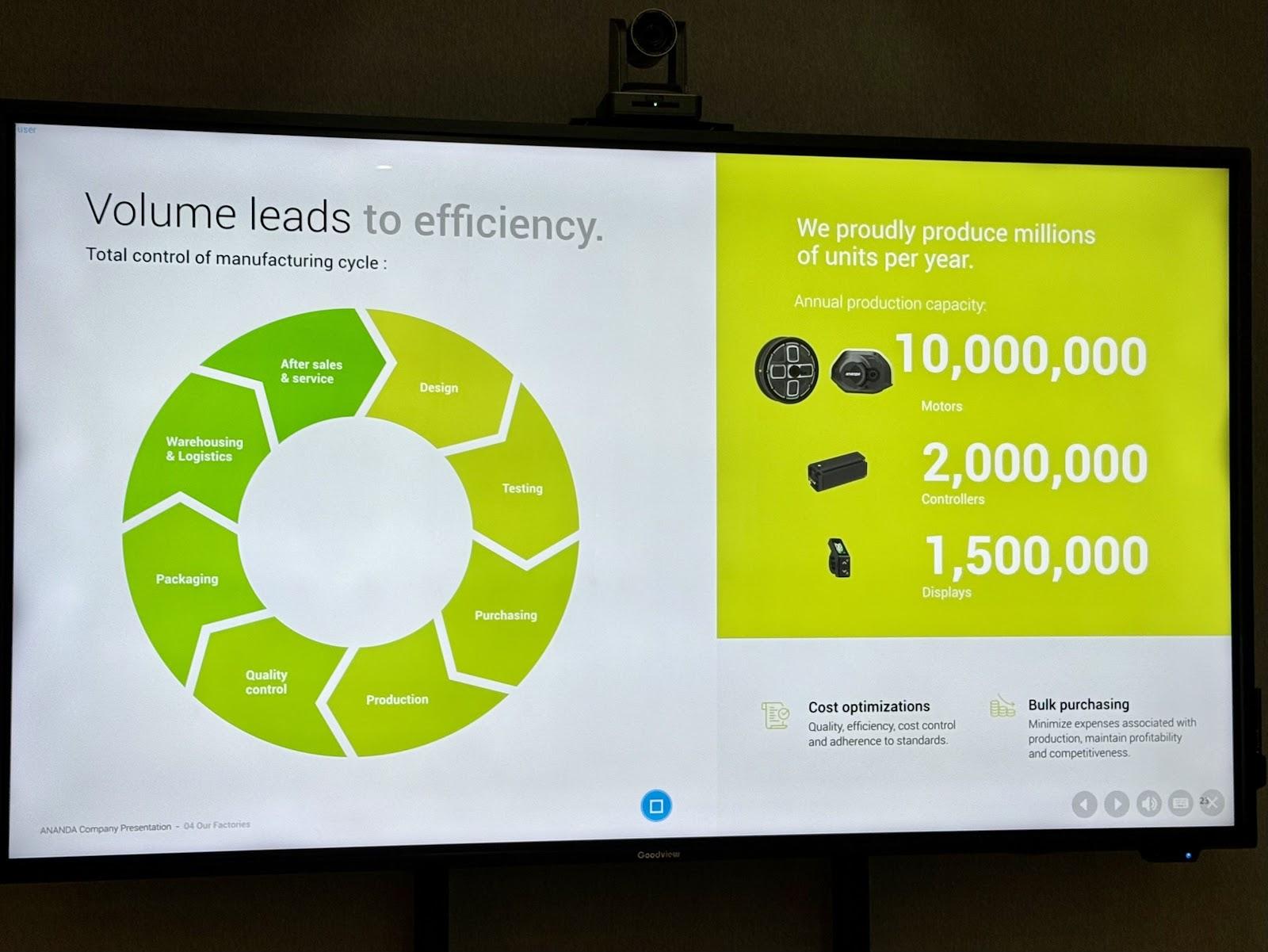

Their global manufacturing footprint includes five factories: four in China (Tianjin, Anhui, Jiangsu, Guangdong), one in Vietnam, and one in Hungary. They employ over 1,000 people and currently produce more than 7 million motors annually, with infrastructure in place to scale up to 10 million motors, 2 million controllers, and 1.5 million displays per year. They are also actively building out a service center in Los Angeles, CA to better support the U.S. market.

Manufacturing Capabilities & Vertical Integration

Ananda’s manufacturing facilities include over 200 automated machines,helping to keep costs low while improving consistency and quality.

Ananda continues to invest heavily in automation to improve production consistency and quality. Their facilities house more than 200 automated machines, including over 70 automated winding machines. They currently run 12 motor production lines and 2 dedicated lines for controllers and displays.

What really stood out during the tour was Ananda’s impressive vertical integration. They don’t just assemble parts sourced from elsewhere—they manufacture their own motors (hub and mid-drive), controllers, sensors, and HMIs. In fact, they’re one of the few Chinese e-bike motor manufacturers with their own SMT (Surface Mount Technology) line for PCBA (Printed Circuit Board Assembly).

This in-house capability allows Ananda to perform all quality control internally, giving them greater oversight and efficiency while allowing for rapid iteration and refinement of their systems.

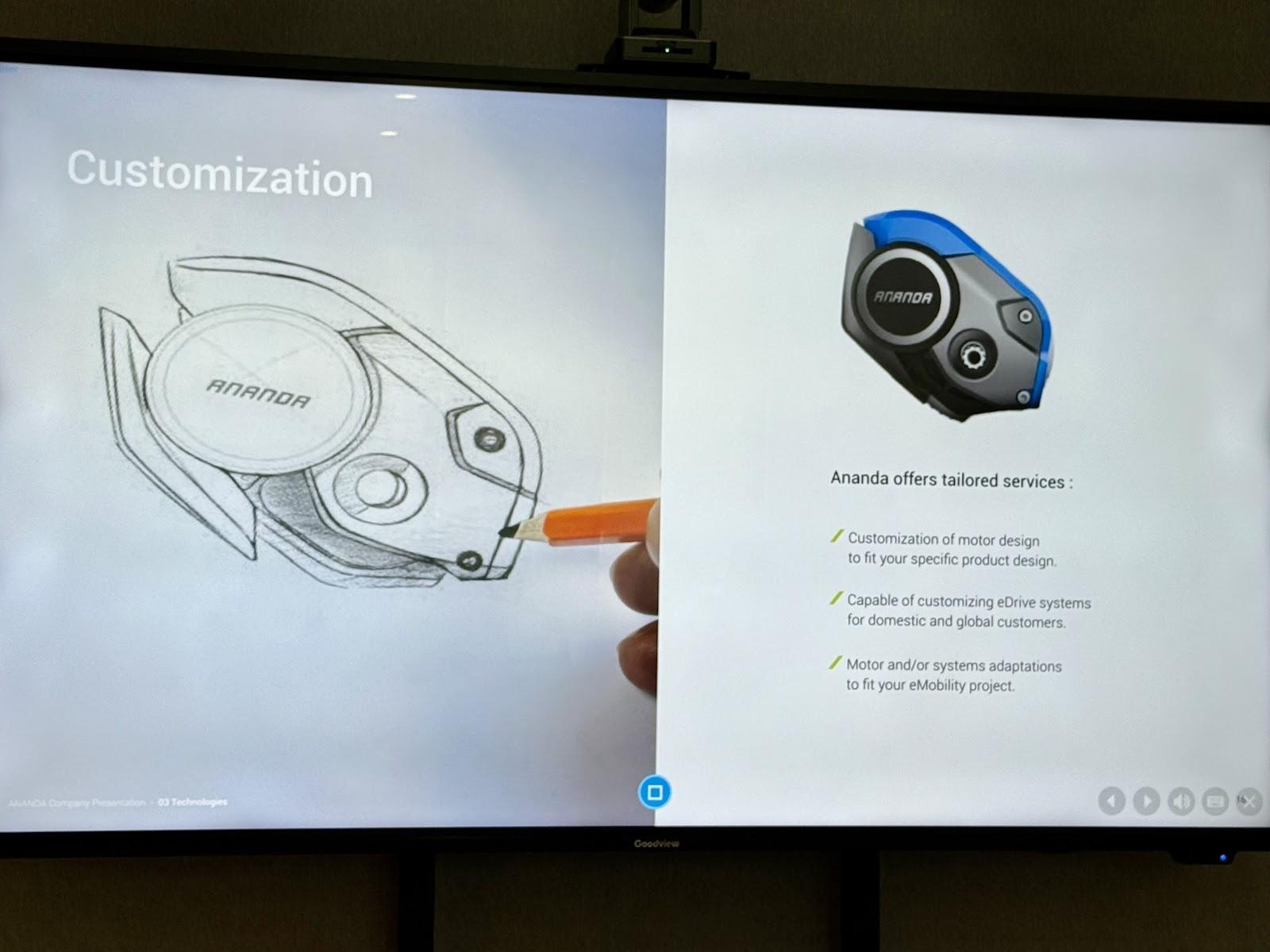

Smart Systems & OEM Customization

One of the most compelling aspects of Ananda’s platform is how deeply customizable it is for OEM partners. Because Ananda manufactures the motor, controller, and display, they can tailor the entire system to a specific brand’s needs. They also make it easier for those brands to support their customers and dealers.

The Ananda Ride App allows OEMs to precisely tune motor response, power delivery, and torque characteristics. Riders often don’t even know they’re on an Ananda system, as the app and system can be white-labeled to the OEM’s brand.

Additionally, Ananda Link is a diagnostic and service tool designed for dealers and OEMs. It enables real-time troubleshooting, software updates, and streamlined after-sales support. These tools combine to create a one-stop solution for brands that want performance, reliability, and flexibility.

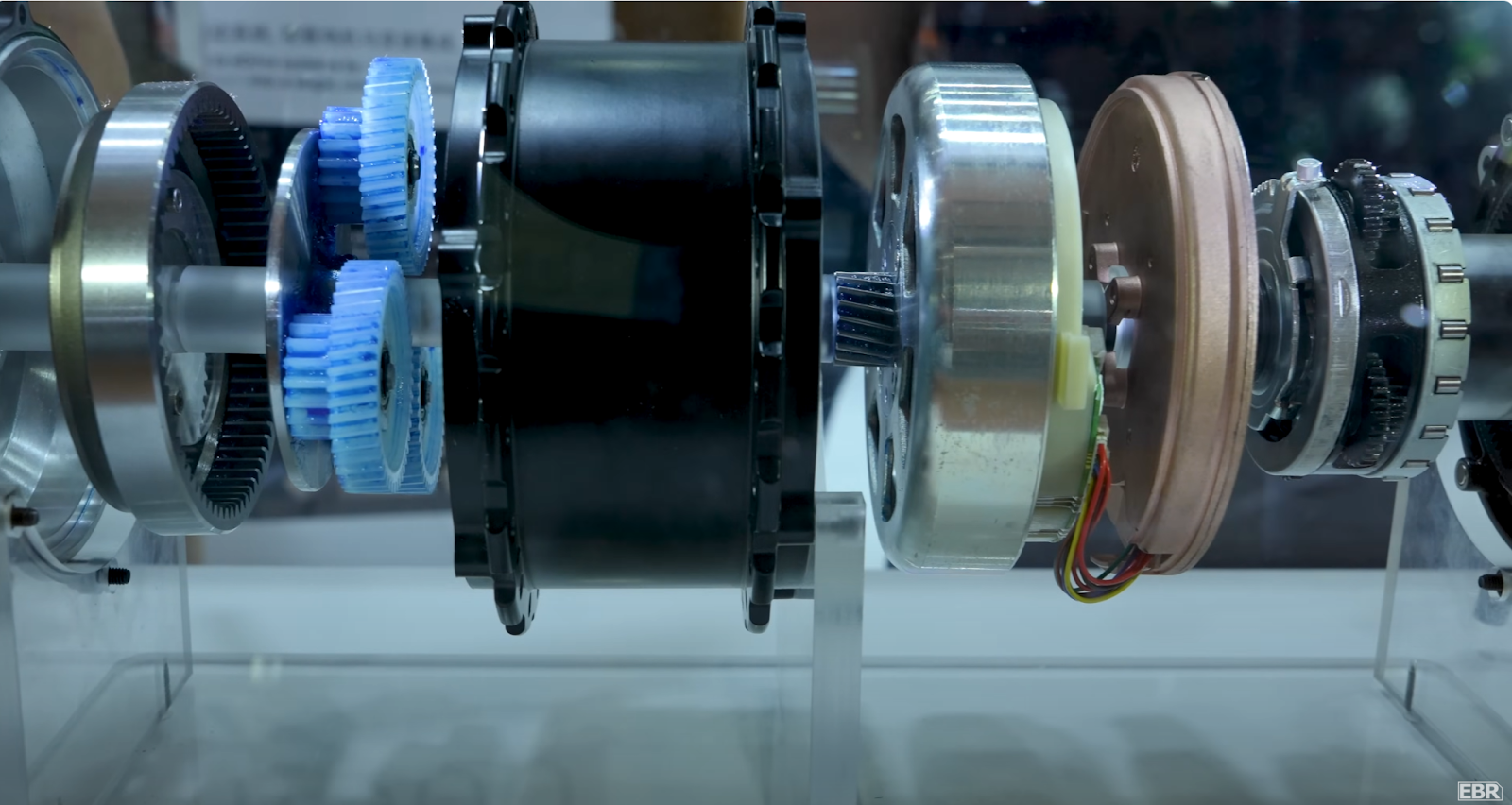

R900: Award-Winning Auto-Shifting Hub Motor

Ananda’s R900 hub motor was a highlight of the trip—and clearly a highlight of China Cycle 2025. The motor system won the Gold Creative Award thanks in large part to its electronic shifting, which allows it to shift more reliably and smoothly under load compared to older mechanical auto-shifting hub designs.

I had the opportunity to test the R900 firsthand. One particularly telling moment was climbing the steep exit of Ananda’s Shanghai HQ parking garage—both from a dead stop and at around 10 mph. In both cases, the R900 shifted quickly and smoothly. While it was limited to the EU’s 15 mph cap during our test, the feel of the system left a strong impression.

What makes the R900 stand out isn’t just the shifting performance. It features an integrated 3-speed gearbox and a hub motor in one compact housing. It’s fully tunable with customizable power output and torque levels, and the electronic shifting system delivers confident performance under stress.

We think this system has potential use for a variety of hub motor e-bikes. Personally, I’d love to see this on the Ride1Up CF Racer. As a rear-hub gravel bike, it would be fascinating to see how the R900’s shifting system performs on mixed terrain.

A Glimpse at the Future: High-Torque Mid-Drive

While still a prototype, Ananda’s full-power (100+Nm) mid drive motor was very impressive.

Ananda also gave us a sneak peek at a new lightweight but high-torque mid-drive motor. I was only able to ride this system around the parking lot and inside their garage, limited to 15 mph, so I can’t yet speak to how it would handle off-road or on singletrack trails. It’s also hard to fully evaluate without back-to-back rides against competitors.

That said, based on specs and initial ride feel alone, this motor impressed me. It seems like a potential contender to Bosch’s Performance Line CX, DJI’s Avinox M1, and Specialized/Brose’s 3.1 motor. It could be a strong option for OEMs looking to deliver high-torque performance without adding excess weight.

Final Thoughts:

Ananda left a strong impression. Their scale, vertical integration, and investment in smart systems position them as a rising force among OEM e-bike system suppliers. The R900 system alone shows that Ananda isn’t just keeping up—they’re pushing boundaries.

A recurring theme throughout my visit to China was that Chinese manufacturers are no longer just producing at scale—they’re leveraging that scale to drive technical innovation. Ananda embodies that evolution, and I’m excited to see more of their systems make their way into bikes around the world.

Leave a Reply