Phylion / Joycube Headquarters in Suzhou, China

Many of our readers may not think twice about who manufactures the battery packs in the e-bikes we review. Most of the attention usually goes to the cylindrical cells inside the pack—most often made by LG, Samsung, or Panasonic.

But here’s what often gets overlooked: not every brand uses the same manufacturer for their battery packs or their battery management systems (BMS). And after more than a decade of testing e-bikes, we can confidently say that who builds the battery pack, and who designs and programs the BMS, often matters more than which of the three big cell suppliers are used.

This perspective came into sharp focus for me during my recent trip to China, where I toured the factories of Phylion and their subsidiary Joycube. Founded in 2003 out of the Institute of Physics at the Chinese Academy of Sciences, Phylion has grown into one of China’s largest battery manufacturers for e-bikes. With over 5000 employees, production capacity exceeding 10.2 gigawatts annually,another 4 GWh currently under construction, their scale is remarkable. Beyond e-bikes, their batteries also power electric vehicles, scooters, mopeds, and energy storage systems.

For the e-bike industry specifically, the spotlight is on Joycube. This subsidiary is entirely dedicated to complete battery pack manufacturing, from designing and programming the BMS to putting each pack through 21 precision steps and extensive safety testing.

After walking their factory floors and seeing this process firsthand, I left with a clear impression: Phylion and Joycube are setting the benchmark for battery pack manufacturing. And based on everything we’ve seen over years of testing e-bikes, this is exactly the type of partner we would recommend without hesitation to any brand looking for a reliable battery supplier.

Touring the Joycube Factory in Suzhou

We started our tour at the Joycube factory in Suzhou, the hub where they design and manufacture battery packs for e-bikes and other light electric vehicles. While Joycube asked us not to disclose the names of the brands they manufacture for, I can say with confidence that the list is both long and impressive—covering some of the largest players in the e-bike and e-moped industry.

Unlike cylindrical cell production (which Joycube sources from Samsung, LG, or Panasonic), the Suzhou facility is where Joycube designs and programs the battery management systems (BMS) and assembles the full battery packs. And as much as people like to get excited about cells being made from raw materials—a process we did see at their Chuzhou factory for prismatic cells—the truth is that for e-bikes, the BMS and pack design often matter more. This is exactly what Joycube specializes in: building packs that are not only efficient, but also exceptionally safe.

Phylion / Joycube’s advanced engineering of their proprietary battery management systems leads to great quality and performance

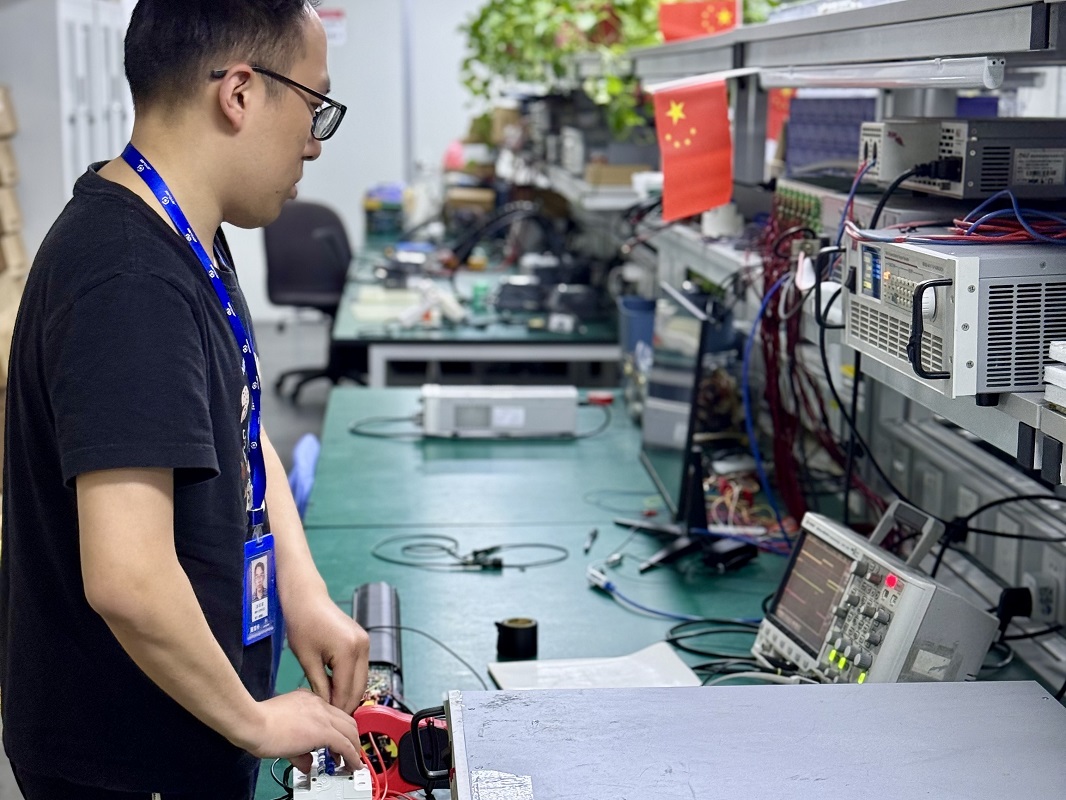

Much of the production we observed followed an assembly line format, but automation played a big role as well. What stood out to me most, though, was watching their engineers actively designing, programming, and testing BMS systems in real time. One highlight of the tour was seeing them custom-design systems for two bike brands we know well from our reviews at EBR—including a model that hasn’t even been released yet. While I can’t share which brands those were, I can say they were both premium names. Seeing firsthand that Joycube is the battery supplier for these brands only reinforced the trust we already had in their products.

And here’s where things got especially interesting. After the tour, I went back and cross-referenced our EBR testing data with the brands we now know use Phylion/Joycube packs. The results showed a clear pattern:

- Better charge retention after long periods of non-use

- Longer overall battery life (with intelligent charging modes that back up Joycube’s claims)

- More consistent power delivery

- More accurate power level readouts on our range tests

- Better performance on our hill tests, especially during the high-stress and high-heat summer months.

- Higher-quality chargers, ports, and overall build quality of the packs themselves

In short, the engineering work happening inside the Suzhou factory shows up directly in how these batteries perform in the real world. Based on what we’ve seen—both in testing and on the factory floor—we can say without hesitation: Phylion and Joycube set a very high bar for e-bike battery packs, and we can 100% recommend them to any brand looking for a reliable, high-quality partner.

Touring the Chuzhou Factory – Where Prismatic Cells Are Made

Much of the prismatic cell production line is done with advanced automated systems

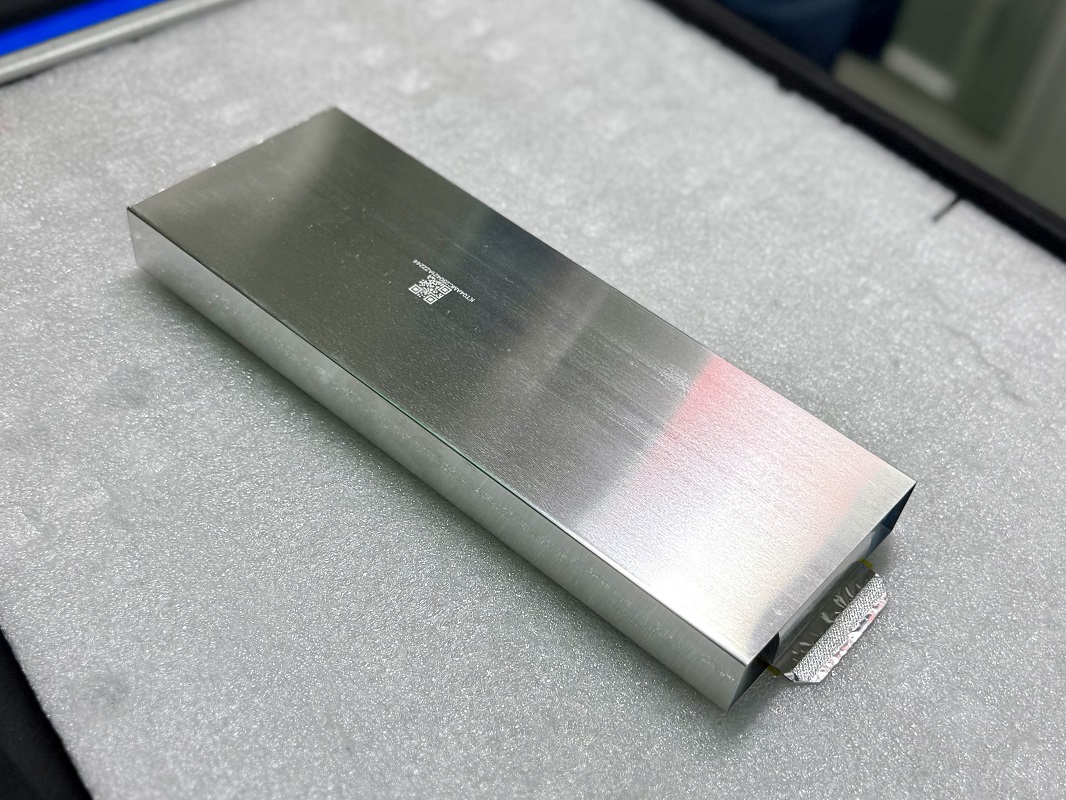

From Suzhou, we traveled to Chuzhou, where Phylion produces its own prismatic cells. Here, Phylion walked us through the entire cell production process: blending the raw materials, forming the electrodes, stacking the sheets, and assembling them into finished cells ready for packs.

The level of precision and safety required is astounding. Prismatic cells are built by layering extremely thin positive and negative electrode sheets with separators in between. Watching these layers come together at high speed through fully automated lines—and staying perfectly aligned without shorting—was one of the more jaw-dropping processes I’ve ever seen in battery manufacturing.

On the left: the positive and negative electrode sheets of a prismatic cell | One the right: a fully-encased prismatic cell

Phylion takes cleanliness and quality control seriously. Before we entered the production floor, we had to suit up in full anti-static gowns, put on face masks, and then pass through a series of anti-static chambers as we moved from one production room to the next. It was clear: this is a tightly controlled environment designed to protect both the product and the people who will one day ride with these batteries.

Safety testing was a major highlight of the Chuzhou tour. Phylion takes their batteries through a series of 21 independent tests. For me, a few tests stood out:

- Drop Test – Batteries are repeatedly dropped from various heights onto concrete floors. What we saw was far harsher than any real-world drop we’ve ever had happen to a pack at the office or at home.

- Overcharge Test – Batteries are charged not only at their standard rate, but also at 2x and 3x the rate, ensuring the cells can safely handle abnormal charging conditions without failure.

- Penetration Test – This was by far the most intense. In this test, a steel pin is driven through the battery to simulate catastrophic damage and force an internal short circuit. The test is performed in a sealed room, and we were only allowed to watch on a monitor. I’ll admit: part of me was hoping to witness a failure and see a pack go into thermal runaway. But every test we saw passed with flying colors. When I asked the operators if they had ever seen one fail, they said no.

Walking out of Chuzhou, I felt much more confident in the safety and durability of products made by Phylion and Joycube. Seeing these tests firsthand leaves no doubt that their cells and packs are designed not just for performance, but for rider safety above all.

Final Thoughts: Why Phylion and Joycube Stand Out

After touring both the Suzhou and Chuzhou facilities, one thing became crystal clear: Phylion / Joycube has earned its place as one of the leading battery pack manufacturers in the e-bike industry.

Everyone in our group walked away from those tours with greater respect not just for Phylion, but for Chinese manufacturing in general—a point worth making given how often we hear comments about Chinese products being “cheap” or “low-quality.” The reality is very different. Phylion / Joycube is producing some of the highest-quality packs in the industry, trusted by some of the best and most recognized e-bike brands.

That trust extends to me personally. Some of the bikes I ride, test, and even store in my own garage rely on Phylion battery packs—and I do so with full confidence in their safety and performance.

Leave a Reply